Market segments

FOMAS Group offers a wide range of rolled rings and open die forgings for bearings, gears, structural and shaft components.

Transmission system

- Gears

-

Immagine

- Bearings

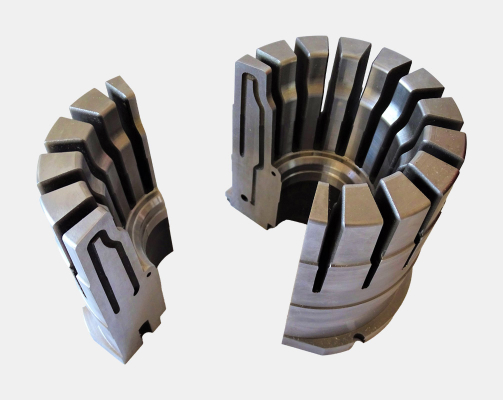

Turntable

- Slewing bearing

-

Immagine

Nacelle and Hub

GEARBOX

- Ring gear

-

Immagine

- Planet gear

-

Immagine

- Sun gear

-

Immagine

- Hollow shaft

-

Immagine

- Bearings

- Main bearing

- Main shaft

- Coupling

Yaw System

- Slewing bearing

- Yaw drive gear

Tower

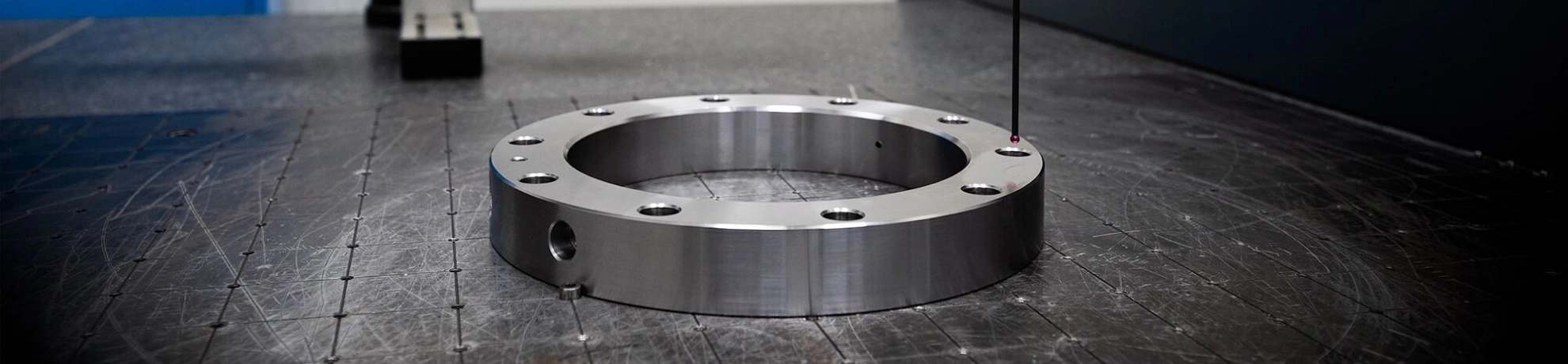

- Flange

-

Immagine

Pitch System

- Slewing bearing

- Pitch drive gear

The components highlighted in this infographic represent a selection of our production range.

To learn more about our full range of solutions or to discuss specific requirements, please visit our Contact section and reach out to us via email.

We offer a wide array of products and solutions for the industrial market and its segments, including:

- Earthmoving and Mining

- Industrial equipment and systems

- Wind power

- Transportation

- Construction

- Biomedical

Forgings and rolled rings

Our forgings and rolled products are available in a wide range of sizes and types of steel and alloys, designed to meet the specific needs of the most demanding specifications. Thanks to our constant pursuit of excellence, we always guarantee the highest quality and use state-of-the-art processes, offering the best product to our business partners.

Our supply chain guarantees the highest Just-In-Time (JIT) delivery standards, reducing the level of stock. We are committed to providing and receiving the materials exactly when needed, thus ensuring the perfect integration of our solutions within the production processes of our customers, with no interruptions.

We can manage high speed and efficient communication through Electronic Data Interchange (EDI), a digital connection that connects primarily our customer’s and our own MRPs. This tool automates both the exchange and processing of demand and deliveries but also enables paperless transfer of all quality and administrative documents related to each delivery eliminating the need of paper documents and manual activities. Therefore, a higher degree of reactivity, precision and visibility can be guaranteed, by immediately and accurately transmitting any information related to forecasts, orders, shipments and modifications, avoiding mistakes and delays, while cutting down the use of paper, in compliance with our commitment towards our ESG objectives.

Furthermore, EDI enables us to significantly speed up both the procurement and production times, while making deliveries quicker, thanks to the instant transmission of information.

The aforementioned approach adds some further, crucial, value in terms of production efficiency, costs and supply chain, with a focus on reducing our environmental impact.

We can provide components at different degrees of processing, based on the vertical integration level required, ranging from raw forging or ring rolling to heat treated thermally processed components, up to complete machining and surface treatments. Furthermore, we can also pre-assemble components.

We have developed state of the art capabilities to produce profiled rings that offer significant advantages compared to the traditional rectangular section rings. Rolling and shaping the metal with a significant degree of precision, to obtain a shape very close to the finished product(s). In so doing, we can reduce material consumption, machining time and the transport costs.

Metal powders

FOMAS Group produces nickel-, iron- and cobalt-based alloy atomized metal powders, under the name MIMETE®, through a VIGA (Vacuum induction melting Inert Gas Atomization) plant. Our powders can be used for additive (Powder Bed Fusion, Directed Energy Deposition and Binder Jetting) and HIP (Hot Isostatic Pressing) manufacturing applications.

Furthermore, we can provide four different categories of PSD (Particle Size Distribution), based on the requests of our customers.

- 3Dprinting (LPBF)

- DED

- CLADDING

- WELDING

- HIPPING

TECHNICAL SUPPORT

Thanks to our experience and expertise in metallurgy, as well as to our deep knowledge of the relevant processes, we can offer our complete support to our customers, during every phase of the purchasing process.

QUALITY

- Spherical metal powders

- Low-friction productS

Quality provides a competitive edge for us, and it permeates every aspect of our activities.

Every cast we carry out undergoes more than 20 tests to guarantee the highest quality.

CERTIFICATIONS

IOur in-house laboratory attests our commitment to quality, providing a reliable guarantee of our product standards. The aforementioned facility enables us to comply with the rigorous sector certifications, while constantly upholding high quality parameters.

A TAILOR-MADE APPROACH

Our approach focuses on providing our customers with customised services, ensuring swift and flexible responses to their needs.

Mold for stamping and injecting plastics, used to produce shells for washbasins

- Metallic powder used: MIMETE® M M300

- PSD: 15 - 45 µm

- Production technology: SLM

Tibial plateau prosthesis for the osseointegration of joints

Metal powder used: MIMETE® N 75

PSD: 15 - 45 µm

Production technology: DMLS

Our Certifications

- ISO 9001

- ISO 14001

- ISO 45001

- ISO 50001

- IATF 16949

- ABS

- LR

- DNV

- BV

- RINA

- PED 2014/68/EU

Our certifications vary according to our production sites. For further information, please visit the Certifications webpage.