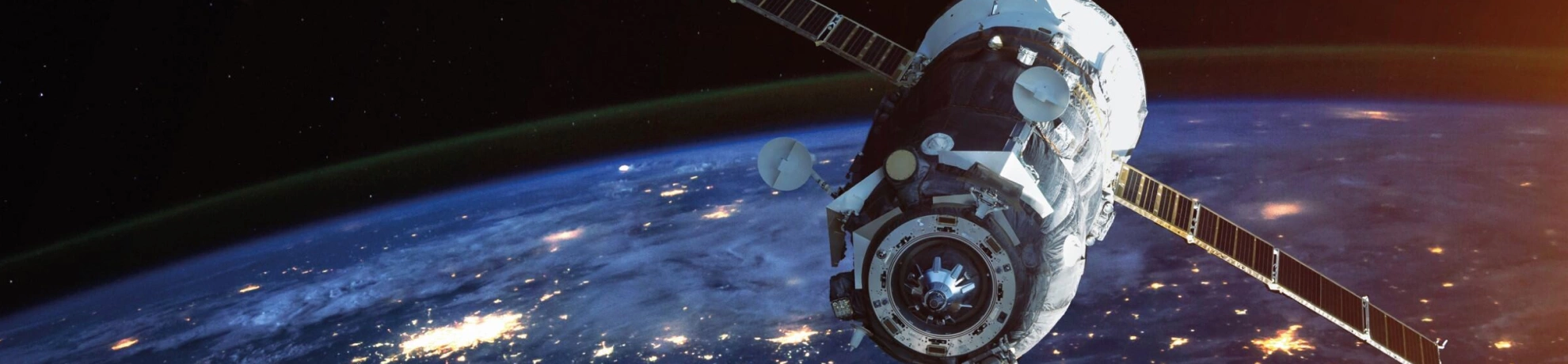

Market segments

Structural interfaces

- Separation ring

- Interface ring

-

Immagine

- Structural ring

Engine

- Main Igniter

-

Immagine

- Flange for Igniter

- Turbine cases

-

Immagine

- Nozzle

-

Immagine

- Rotor disc

- Shroud

- Shaft

Payload parts

- Payload adapter

-

Immagine

- Payload adapter

Immagine

Structural parts

- Fractured item

-

Immagine

- Structural ring

- Interface ring

- Adapter ring

-

Immagine

- Tunnel

-

Immagine

- Bulkhead

-

Immagine

Tanks

- Domes

- Cylinder

Structural parts

- Spar

-

Immagine

- Bracket

-

Immagine

Engine

- Turbine case

- Shaft

- Bearing rings

- Case

The components highlighted in this infographic represent a selection of our production range.

To learn more about our full range of solutions or to discuss specific requirements, please visit our Contact section and reach out to us via email.

We offer a wide range of components, from rolled rings to open die forgings, for the applications focused on the Aerospace and Defense markets:

- Structural rocket parts

- Rocket engines

- Space station modules

- Aircraft engines

- Defense Equipment

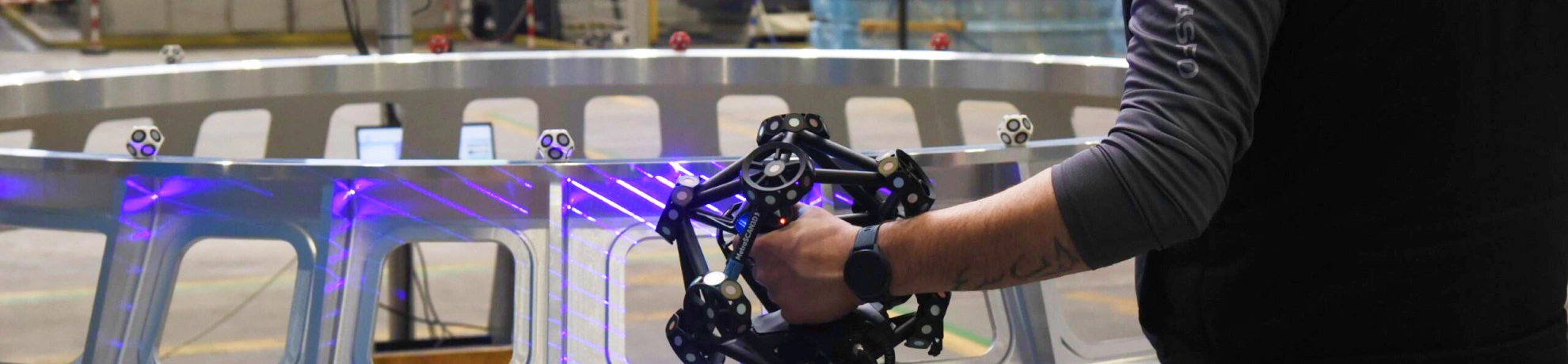

Forgings and Rolled rings

FOMAS Group features a compact supply chain approach within the Aeronautics, Space & Defense sector, as it is able to provide its clients with vertical solutions, between the forging and rolling of metal alloys, together with high-precision mechanical processing, together with the support of all the tests and trials required by such a high-demand market.

The Group offers a wide range of components in Titanium, Aluminum and conventional alloys. Our machinery capabilities and state-of-the-art special processes, together with the system accreditations and the OEM (Original Equipment Manufacturers) qualifications we have achieved allow us to proactively approach the market and to be a viable reference partner in developing new products and programs.

Thanks to the cooperation between the different companies within the Group, we are able to provide a wide range of different components and processing phases to meet the needs of the market and of the programs thereof: from the raw materials, up to the most complex and specialized processes, including the assembly of both parts and composite elements.

Furthermore, our qualified supply chain allows us to finish our deliveries with surface chemical processes and tailored paint jobs.

The synergy we have developed between the FEM-based technology and our significant experience in the field of profile lamination enables us to propose near-net-shape solutions on the market, with a significant advantage to our products.

The consequent reduction in input weight improves the timing of mechanical processes and optimizes treatments, while cutting both environmental impacts and CO2 emissions. All of the above has been developed to provide a win-win context for our customers.

Metal powders

FOMAS Group produces nickel-, iron- and cobalt-based alloy atomized metal powders, under the name MIMETE®, through a VIGA (Vacuum induction melting Inert Gas Atomization) plant.

Our powders can be used for additive (Powder Bed Fusion, Directed Energy Deposition e Binder Jetting) and HIP (Hot Isostatic Pressing) manufacturing applications. Furthermore, we can provide four different categories of PSD (Particle Size Distribution), based on the requests of our customers.

- 3Dprinting (LPBF)

- DED

- CLADDING

- COATING

TECHNICAL SUPPORT

Thanks to our experience and expertise in metallurgy, as well as to our deep knowledge of the relevant processes, we can offer our complete support to our customers, during every phase of the purchasing process.

QUALITY

- Spherical metal powders

- Low-friction products

Quality is a competitive advantage for us, and it permeates every aspect of our activities. Every cast we carry out undergoes more than 20 tests to guarantee the highest quality thereof.

CERTIFICATIONS

Our in-house laboratory attests our commitment to quality, providing a reliable guarantee of our product standards.

The aforementioned facility allows us to comply with the rigorous sector certifications, while constantly upholding high quality parameters.

A TAILOR-MADE APPROACH

Our approach focuses on providing our customers with customised services, ensuring swift and flexible responses to their needs.

CERTIFICATIONS

- ISO 9100

- ISO 9120

- ISO 14001

- ISO 15001

- ISO 50001

- NADCAP MMM

- NADCAP NDE

- NADCAP TT

Our certifications vary according to our production sites. For further information, please visit the Certifications webpage.