Market segments

Subsea

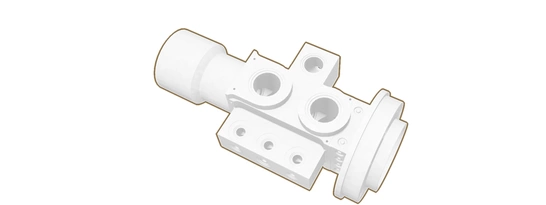

- Spool body/Master Valve Block

-

Immagine

- Spool body/Master Valve Block connector

- Casing hanger

- Wellhead components

Turbular connections

- Riser flange

-

Immagine

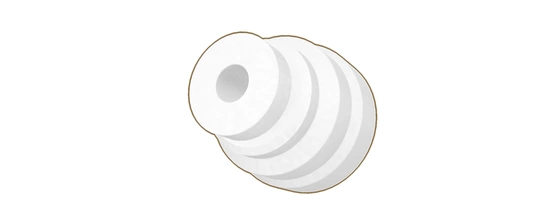

- Pin/Box connector

- Tensioning joint ring

- Flange

- Clamp

Pressure Control

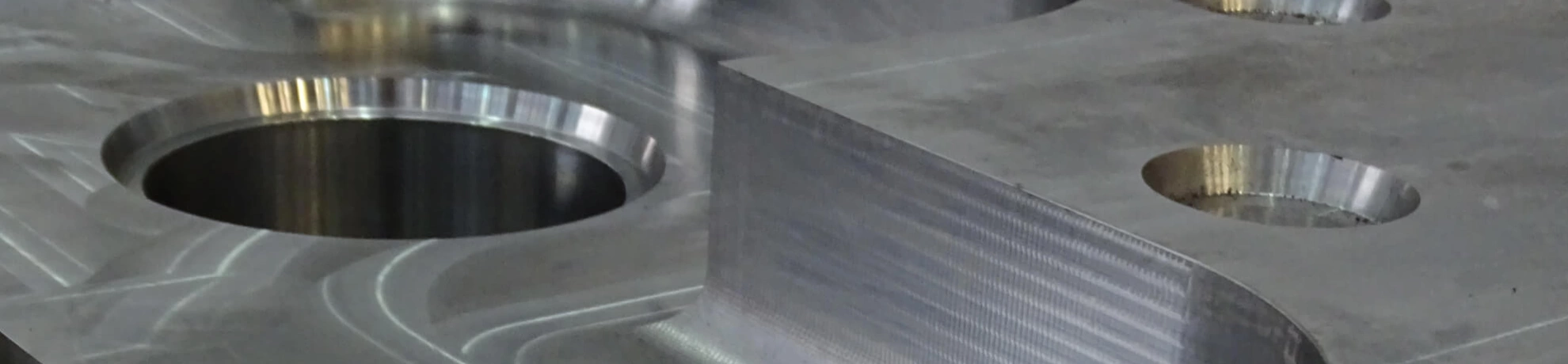

- Annular BOP

-

Immagine

- Blow Out Preventer “BOP”

-

Immagine

- Wellhead components

FPSO

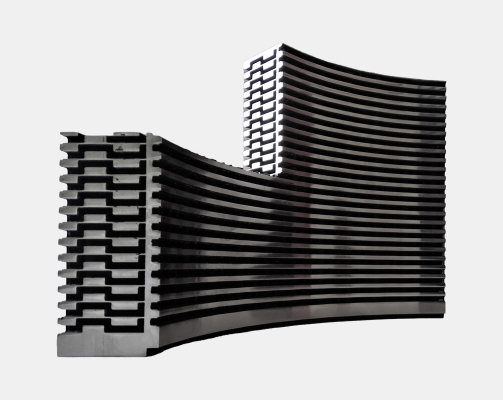

- Turret swivel core (FPSO)

-

Immagine

- Swivel inner and outer ring (FPSO)

- Top plate (FPSO)

- Turret rail (FPSO)

- Anchoring rod

-

Immagine

The components highlighted in this infographic represent a selection of our production range.

To learn more about our full range of solutions or to discuss specific requirements, please visit our Contact section and reach out to us via email.

We offer a wide array of products and solutions for the Oil and Gas market and related segments:

- Offshore and Sub-sea applications

- Onshore and process applications

- Tubular equipment: valves, fittings and pin & box connectors

Forgings and Rolled rings

The market context and the solution provided by FOMAS GROUP

The current global market conditions, including the Oil and Gas sector, may very well be described through the VUCA (Volatile, Uncertain, Complex and Ambiguous) acronym. Within such a context, the main problems customers encounter concern cost control and reliability, as well as to the deliveries, which must occur when agreed and in compliance with the expected quality standards.

FOMAS Group’s answer to such problems lies in its global presence:

through the concept of glocalization, we can provide our customers with proximity, faster delivery times, achieving lower total costs, including ownership and emissions. All of the above is supported by a significant service level, especially when flexibility to satisfy customer needs, proactivity, availability, problem solving and complexity management are concerned.

Our approach enables our customers to benefit from cost reliability mechanisms, as we allocate forging capabilities to reduce the risks connected to the volatility and uncertainty of the market. Thanks to such an approach, the customers have understood the advantages of fostering long-term agreements and relationships, if they want to coexist and have success within the current market conditions.

Therefore, nowadays the customers look no longer only for providers of forgings, but of Solutions.

Based on the requests we receive, we can provide components during different processing phases, based on the vertical integration level required, ranging from raw forging or ring rolling to thermally processed components, up to complete mechanical processing and surface treatments. Furthermore, we can also pre-assemble components.

We apply profiling technologies to the production of rolled rings, rolling and shaping the metal with a significant degree of precision, in order to achieve a form very similar to the finished product(s). In so doing, we are able to cut the consumption of material, the mechanical processing time and the transport costs, thus obtaining a component with the best mechanical properties.

Metal powders

FOMAS Group produces nickel-, iron- and cobalt-based alloy atomized metal powders, under the name MIMETE®, through a VIGA (Vacuum induction melting Inert Gas Atomization) plant.

Our powders can be used for additive (Powder Bed Fusion, Directed Energy Deposition e Binder Jetting) and HIP (Hot Isostatic Pressing) manufacturing applications. Furthermore, we can provide four different categories of PSD (Particle Size Distribution), based on the requests of our customers.

- 3Dprinting (LPBF)

- DED

- CLADDING

- WELDING

- COATING

TECHNICAL SUPPORT

Thanks to our experience and expertise in metallurgy, as well as to our deep knowledge of the relevant processes, we can offer our complete support to our customers, during every phase of the purchasing process.

QUALITY

- Spherical metallic powders

- Low-friction products

Quality is a competitive edge for us, and it permeates every aspect of our activities. Every cast we carry out undergoes more than 20 tests to guarantee its highest quality.

CERTIFICATIONS

Our in-housel laboratory attests our commitment to quality, providing a reliable guarantee of our product standards.

The aforementioned facility allows us to comply with the rigorous sector certifications, while constantly upholding high quality parameters.

A TAILOR-MADE APPROACH

Our approach focuses on providing our customers with customised services, ensuring swift and flexible responses to their needs.

A sizable (diameter: 500 mm) labyrinth valve cage

Metal powder used: MIMETE® V 718

PSD: 15 - 45 µm

Production technology: LPBF

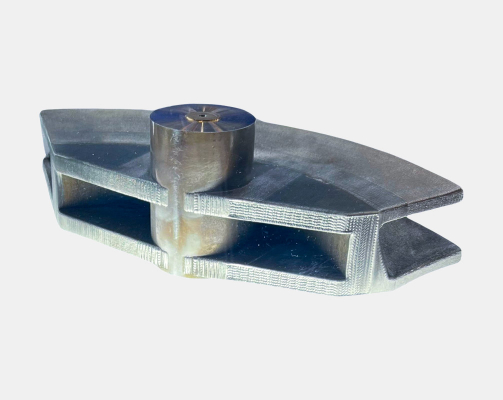

Impeller

Metal powder used: MIMETE® M F51

PSD: 50-150 µm

Production technology: DED

Certifications

- ISO 9001

- ISO 14001

- ISO 45001

- ISO 50001

- ISO 29001

- ISO 3834-2

Our certifications vary according to our production sites. For further information, please visit the Certifications webpage.