Automation and digitisation

These are closely interconnected subjects at the heart of our innovation processes. It is possible thanks to the implementation of specific software and tools for Business Intelligence, Digital twin, Big Data management and analysis, cloud solutions, and Artificial Intelligence.

Our actions are aimed at adopting a lean approach which reduces waste to the point of elimination while optimising the manufacturing processes.

The management and archiving of mega-data is also of fundamental importance to trigger enhancement measures with a view towards sustainability.

Actually, it is the awareness of who we are today that enables us to activate the best decarbonisation solutions and reduction of environmental impact thanks to the introduction of new processes and machinery or through their efficiency.

The grounds of our Innovation

Description

Use of a set of technical tools and procedures which, by appropriately acting on particular devices or instruments, ensure the automatic performance of a given process, the automatic operation of an industrial plant, a public service.

Solutions

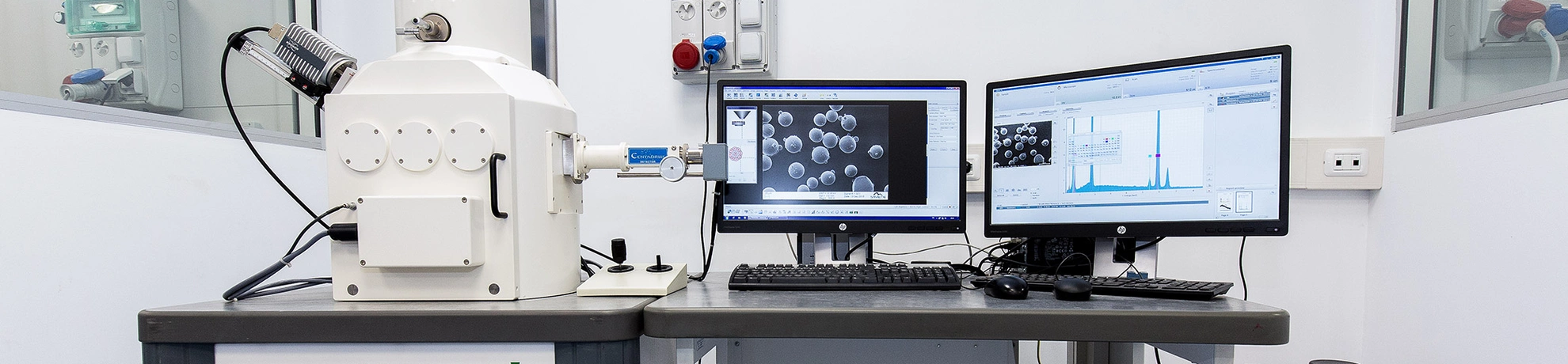

Cloud solutions, Artificial intelligence, Machine learning, Implementation of specific software, 3D measurement technology for reverse engineering and quality control (e.g. monitoring and remote intervention; optimisation of forging, rolling, heat treatment, machining, dimensional inspection, destructive and non-destructive testing).

Description

Conversion of analogue quantities into digital information. Development of simulation programmes capable of predicting the thermomechanical transformation of steels and non-ferrous alloys.

Solutions

Cloud Solutions, Business Intelligence, Use of metallurgical and FEM simulation software.”

Investments

Economic resources and know-how of our staff, two indispensable elements for innovation.

Some of our projects: