Our Quality in Numbers

The FOMAS Group places “quality” at the core of all its operations, in every step of manufacturing and customer service. Quality means ensuring that every forged, rolled or powder metal component complies with all the required standards and customer expectations in terms of performance, reliability and safety.

This commitment translates into a set of practices and standards encompassing:

Careful selection of raw materials and constant monitoring of their properties to ensure that every component in manufacturing complies with the required specifications.

Using state-of-the-art technology and procedures to forge and process metals, for the sake of ensuring the highest quality of the finished product.

Each product goes through an extensive testing process to verify that it complies with all the requirements and specifications. The tests performed range from chemical analysis to mechanical characteristics (low and high temperature). Resistance and durability can also be defined.

Compliance with international standards and obtaining relevant certifications that attest to the quality of FOMAS Group's products and processes because each market has its own, dedicated certification requirements and standards. A commitment that has its roots in the past: FOMAS Group was the first company in Italy (and among the first in Europe) to receive the ASME certification in 1979. Our Group companies pride themselves on the most relevant certifications and accreditations in the sectors we supply:

-

NADCAP and AS/EN 9100 for aerospace;

-

IATF 16949 for the automotive sector;

-

TPG for power generation;

-

ISO 19443 for the nuclear sector.

Cyclic training on new manufacturing methods, technologies and quality standards to ensure that our staff is always up-to-date with the best practices in the industry. Thanks to ongoing training, all our personnel have gained an awareness of product quality and safety.

FOMAS Group places great importance on customer feedback as a tool for an incremental enhancement process. Through the analysis of feedback, the company strives to refine its processes and products to better meet market needs.

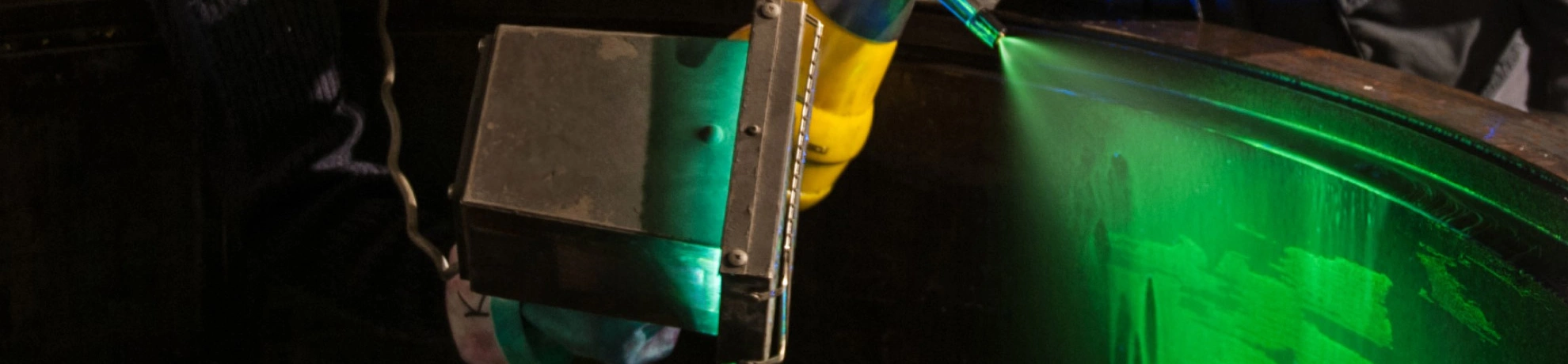

Located within the FOMAS and MIMETE manufacturing facilities, the laboratories are equipped with state-of-the-art technology and precision equipment to carry out extensive testing, examination and analysis of materials and finished products.

Our quality tests thus guarantee compliance with industry standards and ensure long-term performance and reliability of products under various stress regimes and conditions of use.

The laboratories are an added value that underlines the Group's commitment to providing superior quality and highly reliable solutions, meeting the most stringent requirements of our customers.

The competencies of our Laboratory

Materials Analysis

The laboratory performs chemical and physical analyses on incoming materials to check their compliance with the required specifications. This is essential to ensure that only the best raw materials are used during the manufacturing process.

Quality Testing

Each product is subjected to a series of rigorous tests to ensure that it complies with the necessary quality standards. FOMAS' in-house laboratory is equipped with advanced capabilities that go beyond standard mechanical, metallographic and chemical testing, offering significant added value to our testing services. In addition, our laboratories specialise in strength testing, durability analysis and functionality testing.

Development and Innovation

The laboratory also plays a key role in the development of new products and processes. Working in close synch with the R&D department, the lab helps turn innovations into practical and effective solutions.

Certifications

Due to its capabilities and the precision of its processes, the laboratory is accredited in compliance with international standards. This not only boosts confidence in the quality of FOMAS products, but also opens the door to global markets where such certifications are an imperative.

Technical Support

The laboratory provides continuous technical support to the various divisions of the company, ensuring that all operations are in line with the established quality standards. Such support is crucial for quality control during manufacturing and for resolving any technical problems that may arise.

Materials Analysis

The laboratory performs chemical and physical analyses on incoming materials to check their compliance with the required specifications. This is essential to ensure that only the best raw materials are used during the manufacturing process.

Quality Testing

Each product is subjected to a series of rigorous tests to ensure that it complies with the necessary quality standards. FOMAS' in-house laboratory is equipped with advanced capabilities that go beyond standard mechanical, metallographic and chemical testing, offering significant added value to our testing services. In addition, our laboratories specialise in strength testing, durability analysis and functionality testing.

Development and Innovation

The laboratory also plays a key role in the development of new products and processes. Working in close synch with the R&D department, the lab helps turn innovations into practical and effective solutions.

Certifications

Due to its capabilities and the precision of its processes, the laboratory is accredited in compliance with international standards. This not only boosts confidence in the quality of FOMAS products, but also opens the door to global markets where such certifications are an imperative.

Technical Support

The laboratory provides continuous technical support to the various divisions of the company, ensuring that all operations are in line with the established quality standards. Such support is crucial for quality control during manufacturing and for resolving any technical problems that may arise.

Impact on Business

The existence of two accredited in-house laboratories enables FOMAS Group to maintain end-to-end quality control on all its products, reducing the risks associated with non-conformity and improving customer satisfaction. Tangible symbols of the company's commitment to excellence, the laboratories contribute significantly to the recognition of the high quality level of FOMAS brand in the global market.

Accredited laboratories within the Group therefore ensure that products meet the highest standards and foster continuous innovation and process enhancement, thus supporting the company's long-term growth and success.