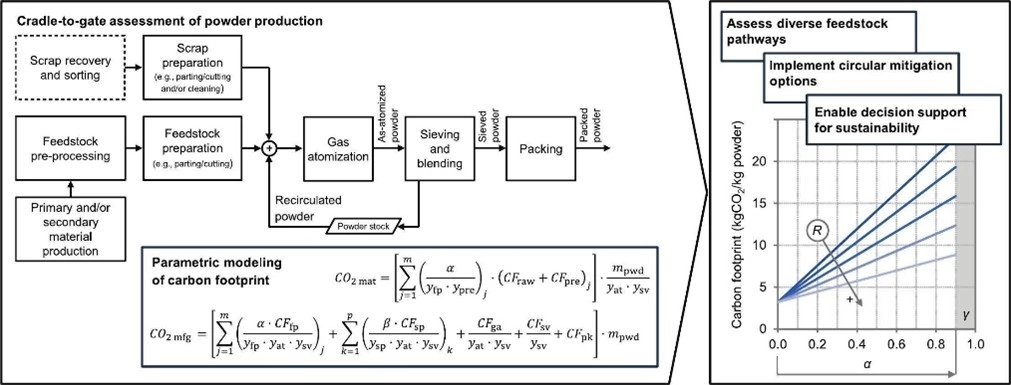

FOMAS Group, through its metal powders production specialized company MIMETE, collaborated on a study that led to the publication of a scientific article introducing the first-ever parametric model designed to calculate the environmental impact of producing stainless steel AISI 316L powders obtained through gas atomization.

Thanks to its expertise in powder production using a VIGA plant and the availability of 316L in its product portfolio, FOMAS Group contributed to the study by providing real industrial data, essential for the development of the model. The success of this project was made possible by the synergy between two strategically important departments within the FOMAS Group: Research & Development and Sustainability, represented by Francesca Bonfanti, R&D Manager, and Maria Guzzoni, Sustainability Manager.

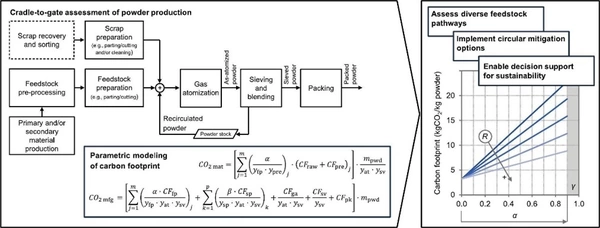

The project, led by Prof. Paolo Priarone from Politecnico di Torino, together with researchers from Politecnico di Torino and Politecnico di Milano, Dr. Federico Simone Gobber and Dr. Stefania Cacace, analyzed and incorporated all stages of the production cycle into the model: from raw material selection to the finished powder, including atomization, sieving, blending, and packaging. The model makes it possible to assess how different choices—such as sourcing strategies—affect the overall environmental footprint.

Moreover, integrating a closed‑loop material flow, by recovering off‑specification powders or utilizing compatible metal scrap as feedstock, plays a crucial role in lowering CO₂ emissions. This approach not only reduces the carbon footprint associated with producing metal powders, but also decreases the reliance on virgin resources.

This study represents an important step toward a more sustainable production, providing companies with practical tools to optimize processes and reduce emissions. FOMAS Group’s contribution aligns with its strategy to adopt an increasingly environmentally conscious business model. Moreover, it strengthens collaboration with academia, already active through initiatives such as ConstructAdd, a project developed with Politecnico di Milano and funded by the European Union, and the funding of doctoral scholarships.

A clear example of how bringing research and business together can drive meaningful change for both industry and the environment.