The ConstructAdd project, a groundbreaking initiative in Additive Manufacturing (AM), is transforming the steel construction industry. As a key partner, MIMETE's expertise in producing high-quality metal powders is contributing to driving innovation and sustainability in the sector.

Unlocking Sustainable Steel Structures with ConstructAdd

ConstructAdd is an EU-funded research project, coordinated by Professor Alper Kanyilmaz of Politecnico di Milano, that aims to overcome existing barriers to AM adoption in the Architecture, Engineering, and Construction (AEC) sector. By using AM in the design, production and maintenance of complex and large steel geometries, the project will enable the creation of more sustainable, efficient, and cost-effective steel structures.

Project Objectives:

-

Develop metal AM material and process guidelines for large-scale components;

-

Select and evaluate powder and wire feedstocks suitable for construction steel production;

-

Design and fabricate demonstrator parts using various AM technologies;

-

Conduct experimental testing to quantify mechanical properties of 3D-printed steel components;

-

Establish a compliance framework for construction parts produced by AM;

-

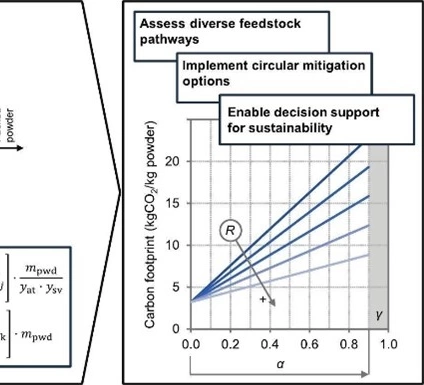

Perform life-cycle analysis to evaluate environmental and economic benefits of AM in the steel industry.

MIMETE's Expertise

As a producer of metal powders for additive manufacturing, the FOMAS Group company’s MIMETE is contributing its expertise to the ConstructAdd project. Its high-quality powders – iron, nickel and cobalt based - are used in various AM technologies and offer:

-

High purity: consistent material properties and minimized risk of defects;

-

Customization: tailored powder production for optimized performance in various AM applications;

-

Quality: ISO/IEC 17025 certified laboratory ensures high-quality metal powders.

As part of the project, following a thorough analysis of commonly used steels in structural applications for civil engineering, ConstructAdd partners have selected an alloy with mechanical properties comparable to S700 grade, thus a high-strength steel alloy. This alloy is widely utilized in the Architecture, Engineering, and Construction (AEC) sector, yet it had not been previously available in metal powder form.

MIMETE has approved the feasibility study and successfully produced S700 high-strength steel alloy powders, branded as MARS S700, in two distinct sizes. These powders are specifically designed to cater to the requirements of two different 3D printing technologies:

-

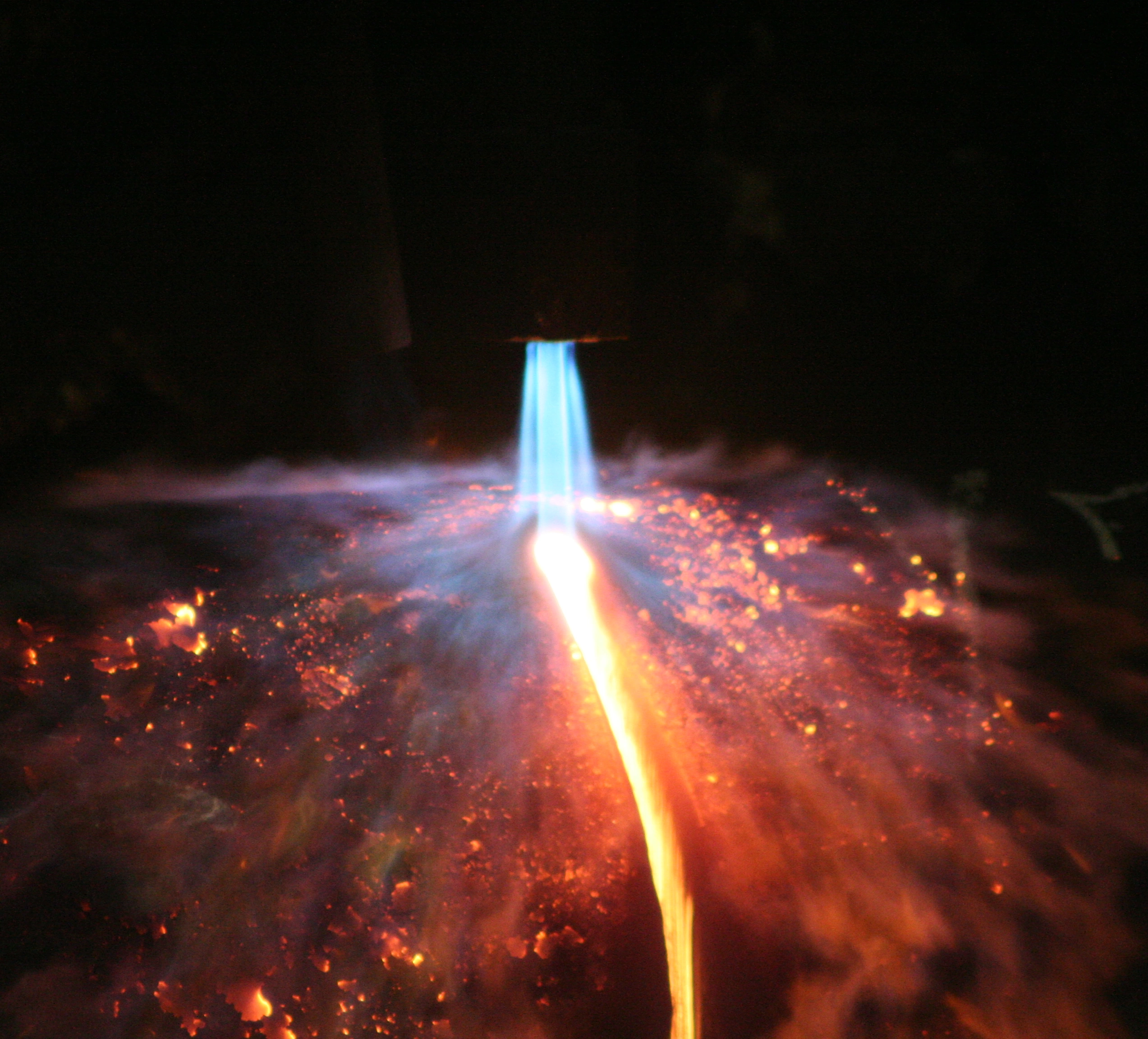

LPBF (Laser Powder Bed Fusion)

-

LDED (Laser Direct Energy Deposition)

By developing MARS S700, MIMETE is pioneering the use of this high-strength steel alloy in metal powder form, contributing to open new possibilities for innovative and sustainable construction solutions.

Transforming the Steel Construction Industry

The ConstructAdd project has far-reaching implications for the steel construction industry. The project is poised to:

-

Increase efficiency: reduce production times and costs with AM technologies enabled by MIMETE's powders;

-

Improve sustainability: adopt Metal 3D printing to reduce environmental footprint and improve operational efficiency;

-

Enhance innovation: drive innovation in the industry with new AM technologies and design tools.

Conclusion

MIMETE's involvement in the ConstructAdd project demonstrates its commitment to driving innovation and sustainability in the steel construction industry. With its high-quality metal powders, the company is helping to unlock a new era of efficient, cost-effective, and environmentally friendly steel structures.

“The research project CONSTRUCTADD EURFCS 101057957 has been funded by the European Union. Views and opinions expressed are, however, those of the authors only and do not necessarily reflect those of the European Union or Research Fund for Coal and Steel. Neither the European Union nor the Research Fund for Coal and Steel can be held responsible for them.”